Categories

New Blog

Why do we need to conduct regular lightning protection inspections on buildings?

March 25 , 20251. Required bythe standard

1)Required by the standard, the national standard is mandatory

GB 50057 Design code for protection of Structures against lightning:

Article 4.5.4 clearly requires that lightning protection devices should be inspected regularly, generally once a year;toflammable and explosive places, the inspection cycle needs to be shortened to once every six months.

Article 6.4.3 stipulates that the grounding resistance value must meet the design requirements (usually ≤10Ω, ≤4Ω in important places), otherwise rectification is required.

2)Industry norms and legal basis

"Work Safety Law": requires enterprises to fulfill their primary responsibility for lightning protection safety, and those who fail to conduct regular inspections and cause accidents must bear legal responsibility.

IEC 62305 series of standards: The International Electrotechnical Commission emphasizes that lightning protection systems must be periodically tested to ensure their effectiveness, especially in areas with high incidence of lightning.

2. Actual on-site requirements

1)Prevent direct damage from lightning strikes

Fire and explosion risks: Lightning strikes can directly ignite flammable materials in places such as gas stations and chemical plants. Testing ground resistance and equipotential bonding can eliminate potential spark discharges.

Structural safety: Corrosion or breakage of lightning arresters may result in the inability to safely discharge lightning current, causing damage to buildings.

2)Protect equipment and systems

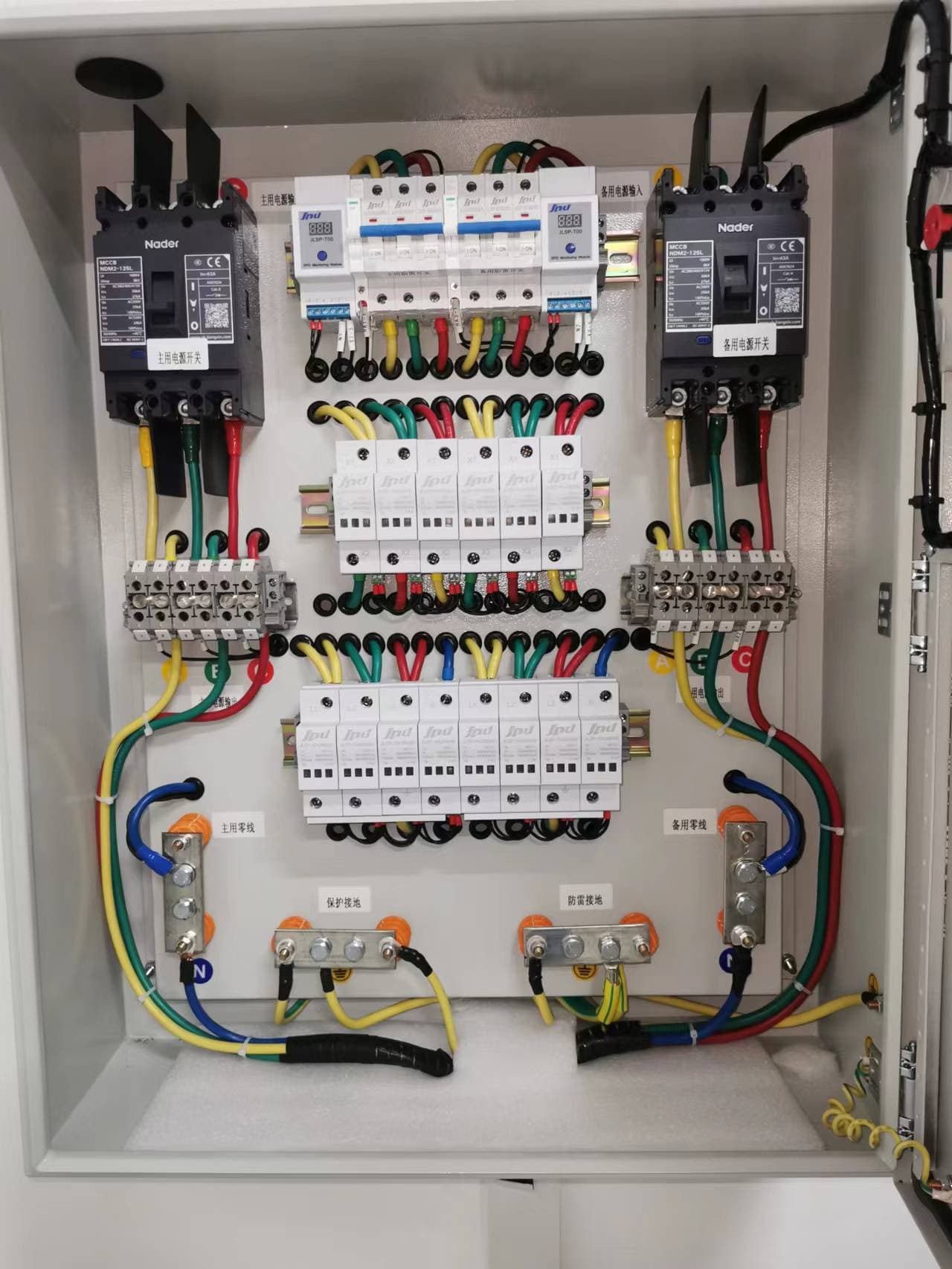

Vulnerability of electronic equipment: Lightning strikes or power surges can damage precision equipment such as servers and medical devices. Testing SPD performance (such as residual voltage and leakage current) can ensure that it effectively limits voltage.

Power system stability: Detection of shielding and wiring compliance of distribution lines can reduce the impact of lightning-induced overvoltage on the power grid.

3)Adapt to environmental changes

Facility aging: Grounding corrosion and SPD component degradation are inevitable over time, and regular inspections can help replace failed components in a timely manner.

Site renovation: Building expansion or use change may damage the original lightning protection system, requiring reassessment of lightning protection level and adjustment of configuration.

4)Necessary needs for special places

Communication base stations and data centers: The high reliability of the lightning protection system must be ensured to avoid business interruption and data loss.

Hospitals and airports: Lightning protection failure may threaten life safety, and detection is a core measure to ensure the uninterrupted operation of critical facilities.

3. Undetected potential risks

1)Legal liability and economic compensation

If a lightning strike accident occurs due to failure to detectit, the company may face administrative penalties, civil compensation or even criminal liability (such as major safety accident crime).

2) Hidden safety risks

For example, if the grounding resistance exceeds the standard but is not discovered, the current cannot be effectively discharged when lightning strikes, which may cause step voltage electric shock or equipment damage.

3) Shortened equipment life

The leakage current of an SPD that has not been detected for a long time will increase, which may accelerate aging and eventually lose its protective function, causing frequent equipment failures.