Energy storage tips

Aug 06, 2024With the acceleration of the global energy transition and the promotion of the "dual carbon" strategy, the energy storage industry, as a key component of the national energy revolution, is ushering in unprecedented development opportunities. With the increase of the proportion of new energy storage in China, the economy of industrial and commercial energy storage is gradually emerging, and the importance of sodium-ion batteries and all-vanadium flow batteries is growing. New trends such as independent energy storage and virtual power plants have also injected new vitality into the development of new energy storage industry. In the design and application of energy storage systems, the total heat dissipation technology of energy storage systems is a key factor to ensure the stable operation of the system. At present, air cooling and liquid cooling are the two most mainstream methods of heat dissipation. Compare from the following six dimensions:

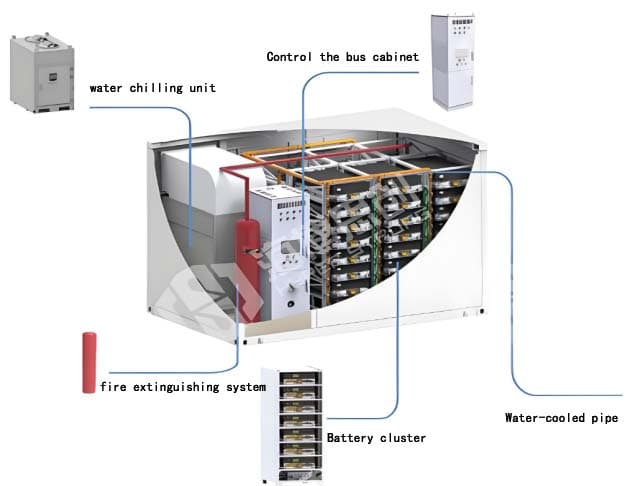

Liquid cooling mode

Ⅰ: the heat dissipation principle is different

Air cooling relies on air flow to take away heat, so that the surface temperature of the equipment is reduced, and the heat dissipation effect will be affected by factors such as ambient temperature and air circulation. Air cooling requires that there be a certain gap between the components of the equipment as an air duct, so the volume of the air-cooled cooling equipment is often larger.

Liquid cooling is to reduce the internal temperature of the equipment through liquid circulation, requiring that the heating equipment components need to have good contact with the heat dissipation plate, and at least one side of the heat dissipation device is smooth and regular; The heat exchange of liquid cooling temperature control is ultimately lost to the outside world through the liquid cooling machine, because the equipment itself is equipped with liquid, so the liquid cooling equipment can achieve a relatively high level of protection.

Ⅱ:Different application scenarios

Air cooling is the most widely used cooling technology at present, and its technical maturity and reliability have been widely verified, especially in low and medium power scenarios, air cooling still occupies a mainstream position.

Liquid cooling is more suitable for large-scale, high energy density energy storage projects. The advantages of liquid cooling are particularly obvious when the battery pack energy density is high, the charge and discharge speed is fast, and the ambient temperature changes are large.

Ⅲ:Different heat dissipation effect

The heat dissipation effect of air cooling is easily affected by the external environment, such as ambient temperature and air flow, so the heat dissipation demand for high-power equipment may not be met.

Liquid cooling has good heat dissipation effect, can effectively control the internal temperature of the equipment, improve the stability of the equipment and extend the service life.

Ⅳ:Different operating power consumption

Air cooling mainly includes the power consumption of air conditioning and electric bin fan;

Liquid cooling is mainly the power consumption of liquid cooling units and electrical bin fans. If under the same conditions, in order to maintain the same temperature, the power consumption of air cooling is usually lower than that of liquid cooling.

Ⅴ:The complexity of the design

The design of air cooling is relatively simple and intuitive, mainly focusing on the installation of cooling fans and the design of air circulation paths.

The design of liquid cooling is more complex, involving the overall layout of the liquid circulation system, the selection of the pump, the circulation of the coolant and the long-term maintenance of the system.

Ⅵ:Costs and maintenance vary

The upfront cost of air cooling is low and maintenance is simple. However, because the protection level is not above IP65, it may lead to dust accumulation in the equipment, which needs to be cleaned regularly, and will increase maintenance costs.

The initial investment cost of liquid cooling is high and the liquid circulation system needs to be maintained. However, due to the liquid isolation in the equipment, its safety is higher, and the coolant needs to be tested regularly due to its volatility.

In summary, the application of air cooling and liquid cooling in the energy storage system has advantages and disadvantages, and the choice of which needs to be determined according to the specific application scenario and demand. If cost and heat dissipation efficiency are key factors, liquid cooling may be more suitable; If you consider easy maintenance and environmental adaptability, air cooling is more advantageous. Of course, it can also be mixed according to the specific situation to achieve better heat dissipation effect. Based on the development concept of "to protect users from lightning intrusion", Anhui Jinli provides a full range of surge protection device from standard products to personalized customization on the basis of focusing on the wind, light, storage and charging industries to meet the needs of customized and high standard application scenarios.